Hardi

Hardi Nozzles

|

Precise, dependable and accountable

HARDI has produced sprayers since 1957 - meeting the needs of all farmers and crops worldwide - a key goal that has demanded the world’s best nozzles. Today the same basic HARDI philosophy promotes the efficient, effective and responsible plant care that ensures quality food production. The nozzle can dominate the sprayer performance. All of the sprayer components are important for safe and effective use, but it is the nozzle that can have the major influence on the performance of the crop protection product that it will apply. The nozzle controls: 0 The throughput [and therefore the dose] 0 Quality of distribution 0 Drop spectrum and coverage

0 Distribution over the target 0 Drop retention or reflection 0The degree of drift and downwind fall-out |

HARDI has combined both design and material selection to produce a range of nozzles that suit the broad demands of both crops and the vast array of agrochemical products available today. This has been the basis for HARDI’s worldwide success. Close co-operation between farmers, advisers, chemical companies, independent and regulatory bodies with HARDI’s agronomists has been the backbone of this continuing success. |

All-round flat fan nozzle. Recommended for all types of pesticide application where optimum coverage is demanded. This nozzle will give you excellent and uniform liquid distribution at boom heights from 14 to 28 in. (20 in. recommended to take care of uneven terrain or boom movements). 0 ISO: Flow, color and outer dimensions 0 Working pressure: 20 to 70 psi 0 Recommended for TWIN sprayers 0 SYNTAL – precision moulded thermoplastic 0 CERAMIC – extremely high durability 0 COLOR TIPS – for safe and easy handling |

LowDrift nozzles are recommended when optimum spraying conditions cannot be achieved (risk of drift) and spraying cannot be postponed. 0 ISO: Flow, color and outer dimensions 0 Working pressure: 20 to 70 psi 0 Restrictor designed for minimum chemical residues 0 SYNTAL – precision moulded thermoplastic 0 CERAMIC – extremely high durability 0 COLOR TIPS – for safe and easy handling This nozzle will give you excellent and uniform liquid distribution at boom heights from 14 to 28 in. (20 in. recommended to take care of uneven terrain or boom movements). |

The HARDI MINIDRIFT nozzle can be used for spraying at sub-optimal weather conditions, when spraying cannot be postponed. The MINIDRIFT nozzle will at low pressures reduce drift to a minimum. 0 Air inclusion nozzle 0 Working pressure: 20 to 80 psi 0 ISO flow, colors, sizes and nomenclature 0 Application rates from 6 to 40 gpa (at 5 mph) 0 SYNTAL – precision moulded thermoplastic This nozzle will give you excellent and uniform liquid distribution at boom heights from 16 to 35 in. The droplet spectrum is coarse to very coarse; safe for drift control but without risking poor coverage and deposition on leaves. The venturi can easily be removed for cleaning the nozzle. |

The HARDI MINIDRIFT DUO nozzle can be used for spraying at sub-optimal weather conditions, when spraying cannot be postponed. The MINIDRIFT nozzle will at low pressures reduce drift to a minimum. 0 Working pressure: 20 to 80 psi 0 ISO flow, colors, sizes and nomenclature 0 30° forward and backward angle 0 Application rates from 7 to 35 gps (at 6 mph) 0 SYNTAL – precision moulded thermoplastic This compact flat spray air-injector nozzle offers droplet spectrum from medium to very coarse; safe for drift control but without risking poor coverage and deposition on leaves. The two angled fans increase the number of droplets and impacts on target compared to normal air injector nozzles. This improves the coverage on dense foliage and vertical targets. The injector can easiily be removed for cleaning the nozzle. |

The HARDI INJET nozzles can be used for spraying at sub-optimal weather conditions, or when spraying cannot be postponed. The HARDI INJET nozzles are recommended for most pesticide applications where reduced risk of drift is demanded. 0 Air inclusion nozzles with greater drift reduction 0 ISO flow, colors and nomenclature 0 Application rates from 3 to fo gpa (at 10 mph) 0 Pressure range: 40 to 140 psi 0 B-Jet border nozzle for precise application near sensitive areas 0 Available in SYNTAL and CERAMIC materials The HARDI INJET & B-JET nozzles can be mounted using the 334083 ISO/INJET cap. |

Five [5] streams of liquid are distributed at different angles and flows by each Quintastream nozzle. Highest flow is from the middle stream and lowest in the outer, overlapping streams. HARDI QUINTASTREAM can be mounted using the filter casing without gasket (725737). 0 The fastest way to convert your sprayer into a high precision fertilizer applicator 0 5 solid streams that minimise crop scorching 0 Particularly important for wide booms at fast speeds 0 ISO standard for easy calibration 0 Turn and Clean key for restrictor removal 0 Boom height 14 to 39 in. Uniquely, this - patent pending - system allows for boom movements that do not influence distribution. |

This nozzle has an 80° spray angle. On boom sizes from 80 132 ft. boom height is often higher than 20 in. above the target. 80° nozzles provide good coverage with reduced drift risk at these higher boom heights and are also adaptable to band spraying. 0 ISO: Flow, color and outer dimensions 0 80° spray angle 0 Working pressure: 20 to 70 psi 0 SYNTAL – precision moulded thermoplastic 0 CERAMIC - extremely high durability The 80° nozzle is suitable for big booms or row crop / band spraying with either low boom or nozzles at droplegs. |

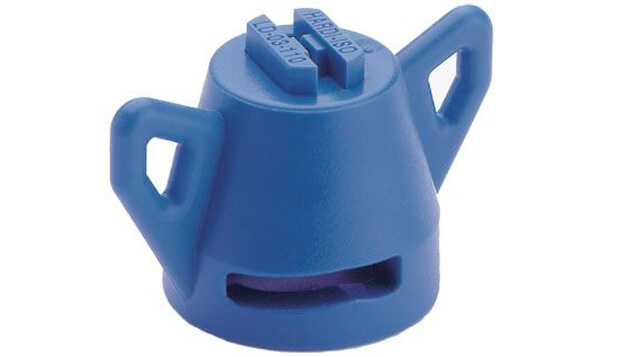

DUOCAP nozzles

|

HARDI foam nozzles are excellent for application of liquid fertilizers. Choose foam nozzles for broad leaf application - the large air inclusion bubbles will be reflected on the leaves and minimize crop damage. The nozzle is used in combination with the 1553 Solid Stream nozzle. 0 Spray angle up to 150° 0 Extremely coarse droplet spectrum 0 Can work at nozzle spacing up to 40 in |

HARDI 1553 Cone nozzles are used without swirl plates for solid stream and with swirl plates for hollow cone and full cone spraying. Use the solid stream for liquid fertilizer on boom sprayers. 0 For application of liquid fertilizer at 10 in. nozzle spacing, with a minimum risk of scorching 0 Flow rates from 0.077 to 8.27 gpm (at 15 to 360 psi) 0 SYNTAL – precision moulded thermoplastic: precise, resistant and durable |

Hollow cone nozzles

0 SYNTAL |

These nozzles are designed so the application volume is the same for all sizes at 14.5 psi and a normal walking speed (2 mph), only the spray width changes. 0 Spray width from 1.5 to 6.6 ft. 0 Even distribution across the swath 0 20 gpa at 14.5 psi |

These nozzles can be used on knapsack sprayers or spray guns, where you want to change the characteristics of the spray cone and the demands for precision is less important. 0 Adjustable by turning the tip 0 From solid stream to hollow cone 0 Available with M18 thread |

The difference between the 4 swirl plates is the droplet size. The blue swirl plate has a very fine droplet spectrum, the grey a fine droplet spectrum and the black swirl plate has a medium droplet spectrum. The white swirl plate has a medium droplet spectrum and is giving a full cone spray. A large drop adaptor (371077) is available for the grey swirl plate. This adaptor changes the droplet spectrum to very large droplets. HARDI 1553 Cone nozzles are used with one of the four available swirl plates for hollow cone and full cone spraying. The hollow cone nozzle can be used for pesticide application on boom sprayers, mistblowers or knapsack sprayers. The HARDI 1553 cone nozzle can also be used without swirl plates for solid stream application |

This nozzle provides an elliptical spray pattern (FlatFan) with a 65° angle. A uniform distribution is obtained, with correct overlap between spray patterns from adjacent nozzles. This nozzle has additional applications for industrial purposes. 0 Recommended pressure range: 20 to 70 psi 0 Recommended boom height above target: 25 to 30 in. 0 SYNTAL |

This nozzle provides an elliptical spray pattern (flat fan) with a 25° angle. The narrow spray angle results in a high impact spray, which is well suited for cleaning as well as for spraying trees and bushes, where a long range is very useful. 0 Pressure range: 2 to 25 bar 0 SYNTAL |

This nozzle consists of a synthetic tip and a blue swirl plate (370156). The droplet spectrum is very fine. The low capacity and extremely fine atomization make this nozzle useful for special purposes such as adjustment of air temperature and humidity in hot climates. 0 Pressure range: 2 to 5 bar 0 Hollow Cone nozzle 0 Very Fine droplets 0 SYNTAL |

Deflector spray nozzle of synthetic material. This nozzle type produces a round spray pattern (360°). The speed of the droplets is low, producing a slowly dispersing cloud. The atomization and dispersion are optimal between 1 to 5 bar. Useful for raising the humidity in greenhouses etc. 0 Pressure range:1 to 10 bar 0 SYNTAL |

Agitation nozzles

|

This nozzle is made for cleaning of the insides of sprayer tanks. The different angles of the 8 solid streams ensure an excellent rinsing of the entire inside surface of the sprayer tank. Hardi recommends the use of a cleaning agent to ensure sufficient cleaning of the tank. 0 Rotating nozzle for tank cleaning 0 8 solid streams at high velocity 0 SYNTAL |